Surface Analysis

Surface Analysis

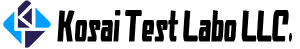

Surface shape observation using optical microscope, scanning electron microscope (SEM), field emission scanning electron microscope (FE-SEM), scanning transmission electron microscope (STEM) or atomic force microscope (AFM). Surface analysis via FE-SEM-EDX, STEM-EDX, secondary ion mass spectrometer (SIMS), time-of-flight secondary ion mass spectrometer (TOF-SIMS), micro Auger electron spectral analyzer (μ-AES) and microscopic laser Raman spectroscopy.

Foreign Substance / Offensive Smell Analysis

Foreign Substance / Offensive Smell Analysis

Foreign substance analysis as well as product/part failure analysis is carried out using energy dispersive X-ray fluorescence analysis apparatus, SEM-EDX, FT-IR, microscopic laser Raman spectroscopy, X-ray diffractometer (XRD) etc.

Generated gas analysis, outgas analysis sensory analysis and offensive smell analysis are conducted using headspace-GC/MS analysis, thermal desorption-GC/MS analysis, SPME-GC/MS analysis, IC, HPLC, LC/MS etc. in order to give odor evaluations.

Car interior Fabric Evaluation

Car interior Fabric Evaluation

We evaluate each car maker’s interior fabrics using a combination of light (weather) resistance testing (sunshine weather meter, xenon weather meter, super weather meter, UV carbon arc-type fade meter, outdoor light resistance test), glass fogging test, combustion test, tensile test, odor test, water resistance test, ELV analysis, dust adhesion test, chemical resistance test, dynamic friction coefficient measuring, abrasion test (Taber abrasion, flat surface abrasion, customized abrasion etc.), volatile organic solvent (VOC) analysis etc.

Reliability Assessment

Reliability Assessment

Reliability assessments are carried out using various light (weather) resistance tests (Sunshine weather meter, xenon weather meter, super weather meter, UV carbon arc-type fade meter, outdoor light resistance test), salt spray testing and thermal shock testing.